SOPRASEAL® LM 203 SKU: A502

SOPRASEAL® LM 203 SKU: A502

SOPRASEAL LM 203 is a one-component spray applied non-permeable air barrier membrane used in wall construction. SOPRASEAL LM 203 is a water-based, ultra low VOC liquid product composed of a modified rubber formulation for elongation. This non-flammable, non-permeable air barrier provides moisture protection behind wall claddings such as brick, siding, metal panels, EIFS and stucco. Utilization of a slipsheet is required for stucco cladding.

Product Properties

- Air Permeability ASTM ASTM E2178

- Air Permeability ASTM ASTM E2357

- Air Permeability ASTM ASTM E283

Installation

To apply SOPRASEAL LM 203 mix the product until thoroughly blended. Use a ¾” (19 mm) nap roller, paint brush or spray equipment to apply. Please refer to SOPREMA specifications and installation instructions for additional application guidelines prior to use.

Testing & Approvals

Related Products

SENTINEL® MOLDED UNIVERSAL CORNERS

SENTINEL MOLDED UNIVERSAL CORNERS are injection molded, unreinforced flashings that are used to flash a variety of irregular details or…

View Product

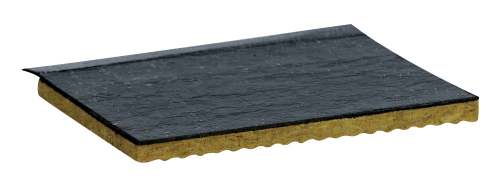

2-1 SOPRASMART ROCK

2-1 SOPRASMART ROCK is a high performance panel composed of an SBS-modified bitumen base membrane and SOPRAROCK high density mineral…

View Product

COLPHENE® SP 3.0

COLPHENE® SP 3.0 (sanded, polyolefin) is a proprietary formulation of elastomeric styrene-butadiene-styrene (SBS) polymer-modified bitumen, reinforced with a high-quality random glass fiber mat.

View ProductRelated Projects

JP Morgan Chase – New York, New York

JP Morgan Chase turned to SOPREMA for a permanent solution to several unique waterproofing issues. The answer was a fully reinforced, low odor ALSAN RS 260 LO PMA System with a slip resistant surfacing layer that offers a 20 year guaranteed waterproofing solution.

Fayetteville Area System of Transit Multimodal Project – Fayetteville, North Carolina

The original design selected for the center left the project over budget, so the contractor and architect had to go back to the drawing board. After researching additional options, both Baker Roofing and Gantt Huberman Architects felt very comfortable with SOPREMA’s proven history and the ability to meet the Buy American requirement, so they selected the SENTINEL® line for the project.