SOPRAJOINT® SKU: S800

SOPRAJOINT® SKU: S800

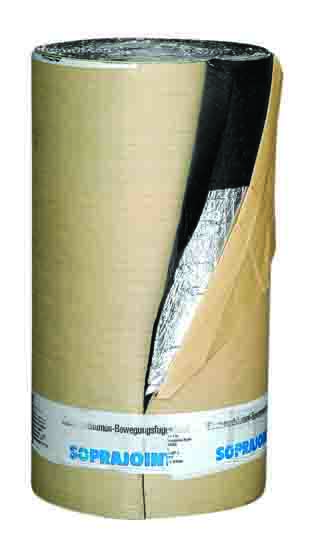

SOPRAJOINT® is an SBS-modified bitumen expansion joint membrane for use in approved multi-ply membrane and flashing assemblies. SOPRAJOINT is composed of a proprietary formulation of elastomeric styrene-butadiene-styrene (SBS) polymer modified bitumen and is reinforced with a tough, dimensionally stable non-woven polyester mat. The topside is surfaced with polyolefin burn-off film to optimize heat welding while the underside is surfaced with a foil bond breaker and a protective polyolefin release film that is removed during application.

Product Properties

- Type Membrane Accessories

Installation

Prior to installation, unroll SOPRAJOINT onto the roof surface and allow to relax. Place SOPRAJOINT in desired position over expansion joint and back roll the product. SOPRAJOINT is heat welded on both sides of the foil bond breaker. Subsequent approved inter-ply or cap ply membranes are applied to SOPRAJOINT via heat welding.

Related Products

SOPRANATURE® DRAIN PLATE 60

SOPRANATURE DRAIN PLATE 60 is a 2.5 in tall, three-dimensional plastic drainage structure for green roofing systems. Unlike thin, flexible…

View Product

SOPRAFLOR AU

SOPRANATURE SOPRAFLOR AU is optimized for fertility, workability and longevity. The medium of choice for rooftop farms for the production…

View Product

SOPRALAST® 50 TV ALU SANDED

SOPRALAST 50 TV ALU SANDED is a SBS-modified bitumen membrane used in roofing assemblies. SOPRALAST 50 TV ALU SANDED is…

View ProductRelated Projects

Placer County Water Agency – Auburn, California

In 2015, the Placer County Water Agency took on a tear-off roofing project, in which SOPREMA products were used. SOPREMA was the right choice for this project because the breadth of products met the designer’s needs, including meeting California Title 24 energy efficiency standards with the use of ENERGY STAR® rated SOPRASTAR® Flam. Another appealing aspect was the versatility of SENTINEL® P150, which allowed coverage for the vertical walls throughout the roofing system.

ANB Bank – Denver, Colorado

When the Denver ANB Bank was to go through a remodel, SOPREMA’s COLPHENE® LM BARR product was selected to waterproof the building. With a tight deadline and existing concrete preparation to take into consideration, COLPHENE LM BARR was the perfect solution due to its excellent performance qualities. With COLPHENE LM BARR’s STPE moisture cure technology, the new and improved ANB Bank will have a continuous waterproofing layer that can withstand extreme cold and high temperatures without cracking or softening for many years to come.