ALSAN Trafik PU 421 SKU: 00513175, 00513176

ALSAN Trafik PU 421 SKU: 00513175, 00513176

ALSAN TRAFIK PU 421 is a two-component, low odor, aliphatic polyurethane elastomeric topcoat. This topcoat provides excellent adhesion to SOPREMA polyurethane system base coats for application of SOPREMA polyurethane coating systems. ALSAN TRAFIK PU 421 is recommended for light and heavy-duty pedestrian and vehicular applications.

Product Properties

- Material Polyurethane

- Technology Polyurethane

Installation

Thoroughly mix ALSAN TRAFIK PU 421 Part A prior to combining. The volume mixing ratio is 4 gallons Part A to 0.4 gallons Part B (0.4 gallons is 2.6 pints). Combined components should be mixed using a jiffy blade mixer at slow speed for at least 2 – 3 minutes. ALSAN TRAFIK PU 421 is applied to the approved area via roller, trowel or notched squeegee. The resin should be applied evenly onto the surface at a wet film thickness of 15 -20 mils (0.4 – 0.5 mm).

Related Products

SENTINEL® P150 HFB

SENTINEL P150 HFB is a high-performance, fleece-backed, thermoplastic polyvinyl chloride (PVC) membrane designed for both steep and low slope applications….

View Product

ELASTOPHENE® LS FR GR

ELASTOPHENE LS FR GR (low slope, fire retardant, granulated) is an SBS-modified bitumen cap ply for use in approved multi-ply…

View Product

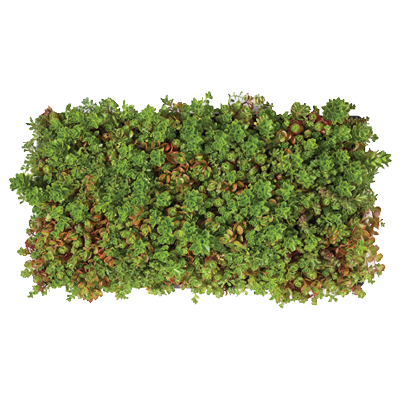

SOPRANATURE® SEDUM TILES

SOPRANATURE SEDUM TILES have a coconut fiber base to assure effective rooting of plants to the underlying growth medium and…

View ProductRelated Projects

Northeast Louisiana State Office Building – Monroe, Louisiana

As an approved manufacturer for the State of Louisiana, the decision makers at the Facility Planning and Control Department were assured that the products installed offered unsurpassed quality. The final assembly was designed to meet FM Approvals 1-90 wind uplift test and proves to protect the building for many years to come.

First Market Tower – San Francisco, California

Multiple SOPREMA systems were installed on this 23,500 square foot project. From the COLPHENE H hot applied, rubberized asphalt system to the use of ALSAN RS for the complex details, there was a solution for every aspect of this project.