ELASTOPHENE® HS SANDED SKU: 00564

ELASTOPHENE® HS SANDED SKU: 00564

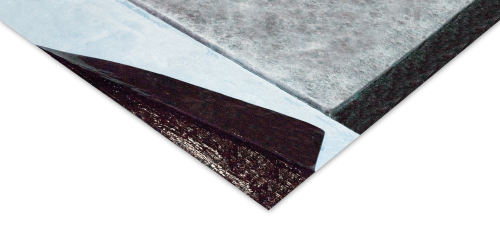

ELASTOPHENE HS Sanded (high strength) is an SBS-modified bitumen base ply for use in approved multi-ply membrane and flashing assemblies. ELASTOPHENE HS Sanded is composed of a proprietary formulation of elastomeric styrene-butadiene-styrene (SBS) polymer modified bitumen and is reinforced with a tough, dimensionally stable composite polyester/glass fiber reinforcement. The topside and underside are surfaced with fine mineral aggregate to facilitate cold adhesive application.

Product Properties

- ASTM ASTM D6162

- Components Base Ply

- Installation Method Cold Adhered, Asphalt Adhered

- Reinforcement Composite

- Thickness (minimum) 110 mils (2.8 mm)

- Thickness (nominal) 118 mils (3.0 mm)

- Topside Sanded

- Underside Sanded

Installation

Prior to installation, unroll ELASTOPHENE HS Sanded onto the roof surface and allow to relax. Place ELASTOPHENE HS Sanded in desired position and back roll the product. Apply approved cold adhesive following manufacturer specifications. ELASTOPHENE HS Sanded is then rolled into the cold adhesive and subsequently rolled with a weighted roller. Subsequent approved inter-ply or cap ply membranes are applied to ELASTOPHENE HS Sanded via cold adhesive. Refer to the SOPREMA SBS Roofing Guide for additional application guidelines.

Testing & Approvals

Related Products

SENTINEL® PREFABRICATED CORNERS

SENTINEL PREFABRICATED CORNERS are manufactured from fiberglass reinforced 60 mil PVC membrane and intended to flash 90 degree outside and…

View Product

SOPRANATURE® SOPRAFILTER

SOPRANATURE SOPRAFILTER is a fabric made of a non-woven needle punched polypropylene and polyester fibers. SOPRANATURE SOPRAFILTER is used as…

View Product

2-1 SOPRASMART BOARD

2-1 SOPRASMART BOARD is a high-performance factory laminated panel combining an SBS-modified bitumen base membrane and SOPRABOARD an asphaltic roof…

View ProductRelated Projects

McNeese State University – Lake Charles, LA

Museum of the American Revolution – Philadelphia, Pennsylvania

Multiple SOPREMA products ranging from ELASTOPHENE® Flam to the SOPRANATURE® vegetated roofing system were used to complete this project. The Museum of the American Revolution is unique in the fact that it has an exposed SBS roof membrane, extensive vegetated roofs, terrace roofs with pavers and even has some vegetated wall systems. The building resembles 1800’s architecture with a modern flare.