ELASTOPHENE® PS 2.2 SKU: 00500

ELASTOPHENE® PS 2.2 SKU: 00500

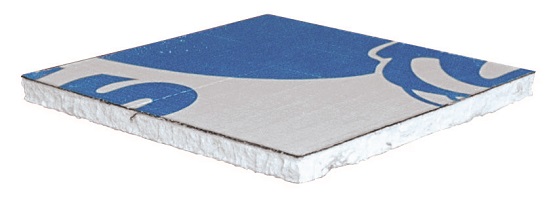

ELASTOPHENE® PS 2.2 is an SBS-modified bitumen base ply for use in approved multi-ply membrane and flashing assemblies. ELASTOPHENE PS 2.2 is composed of a proprietary formulation of elastomeric styrene-butadiene-styrene (SBS) polymer modified bitumen and is reinforced with high quality random glass fiber mat. The topside is surfaced with polyolefin burn-off film and the underside is surfaced with fine mineral aggregate to facilitate cold adhesive and hot asphalt applications.

Product Properties

- ASTM ASTM D6163

- Component Base

- Installation Method Cold Adhered, Asphalt Adhered

- Reinforcement Glass Fiber

- Thickness (minimum) 79 mils (2.0 mm)

- Thickness (nominal) 87 mils (2.2 mm)

- Topside Burn Off Film

- Underside Sanded

Installation

Prior to installation, unroll ELASTOPHENE PS 2.2 onto the roof surface and allow to relax. Place ELASTOPHENE PS 2.2 in desired position and back roll the product. Apply approved cold adhesive or hot asphalt following manufacturer specifications. ELASTOPHENE PS 2.2 is then rolled into the cold adhesive or hot asphalt and subsequently rolled with a weighted roller. Subsequent approved inter-ply or cap ply membranes are applied to ELASTOPHENE PS 2.2 via heat welding. Refer to the SOPREMA SBS Roofing Manual for additional application guidelines.

Testing & Approvals

Related Products

Bitutak MB Smooth

BITUTAK® MB is a 3.8 mm (150 mils) APP (Atactic Polypropylene) modified bitumen roofing membrane for approved multi-ply membrane and…

View Product

SOPRASEAL® Xpress G

SOPRASEAL Xpress G is an exterior grade, inorganic faced gypsum board with an air and vapor barrier factory applied to…

View Product

ELASTOPHENE® HR FR GR

ELASTOPHENE HR FR GR (high resistance, fire retardant, granulated) is an SBSmodified bitumen cap ply for use in approved multi-ply…

View ProductRelated Projects

Fayetteville Area System of Transit Multimodal Project – Fayetteville, North Carolina

The original design selected for the center left the project over budget, so the contractor and architect had to go back to the drawing board. After researching additional options, both Baker Roofing and Gantt Huberman Architects felt very comfortable with SOPREMA’s proven history and the ability to meet the Buy American requirement, so they selected the SENTINEL® line for the project.

Holiday Inn Express – Medina, Ohio

SOPREMA®’s SOPRASEAL® Stick VP self-adhered vapor-permeable air barrier membrane was installed to ensure a continuous air barrier with no moisture infiltration for this wall assembly requiring a “breathable” characteristic. It creates a solid barrier against air infiltration and exfiltration, which minimizes associated energy loss and condensation problems.