ALSAN® RS 260 LO FIELD SKU: L-RS050S

ALSAN® RS 260 LO FIELD SKU: L-RS050S

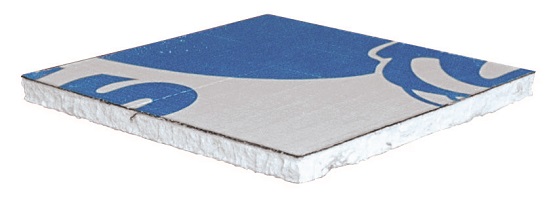

ALSAN RS 260 LO FIELD is a high-performance, low odor, rapid-setting, polymethacrylate (PMA) liquid resin. ALSAN RS 260 LO FIELD resin is combined with fleece fabric to form a monolithic, self-flashing and self-adhering reinforced waterproofing membrane. ALSAN RS 260 LO FIELD is available in a summer or winter formulations.

Product Properties

- Installation Method 2 Part

- Material Liquid

- Technology PMA

Installation

Using a slow-speed (200 to 400 rpm) mechanical agitator, thoroughly mix the entire container of resin for two minutes before use. Only catalyze the amount of material that can be used within 10-15 minutes. Add the pre-measured catalyst to the resin component and stir for two minutes and apply to the substrate. Refer to the catalyst information found on the second page of the PDS. Apply without dilution or thinning.

After mixing, apply ALSAN RS 260 LO FIELD to prepared substrate at the required consumption using a roller or brush. The resin should be applied evenly onto the surface using care not to spread too thin or pool in low areas.

Refer to the ALSAN RS Roofing Technical Manual for additional application guidelines.

Testing & Approvals

Related Products

SOPRASEAL® LM 203

SOPRASEAL LM 203 is a one-component spray applied non-permeable air barrier membrane used in wall construction. SOPRASEAL LM 203 is…

View Product

DUOTACK® 365

DUOTACK® 365 is a low rise, two component polyurethane adhesive. DUOTACK 365 is used to adhere insulation and cover boards…

View Product

SOPRASEAL® Xpress G

SOPRASEAL Xpress G is an exterior grade, inorganic faced gypsum board with an air and vapor barrier factory applied to…

View ProductRelated Projects

Perry Monument – Put-in-Bay, Ohio

At 352-feet, it is among the tallest monuments. The world’s most massive Doric column was constructed by a multi-state commission from 1912 to 1915 “to inculcate the lessons of international peace by arbitration and disarmament”.

Michigan State University – East Lansing, Michigan

The facilities management staff at Michigan State University is responsible for over 17,000,000 sq.ft. of roofs. When the staff determines that a re-roof of one of the 580 buildings on campus is necessary, options are limited to known and trusted manufacturers that offer systems with superior in-field performance, such as SOPREMA.