COLPLY® ADHESIVE SKU: A230, A232, A233

COLPLY® ADHESIVE SKU: A230, A232, A233

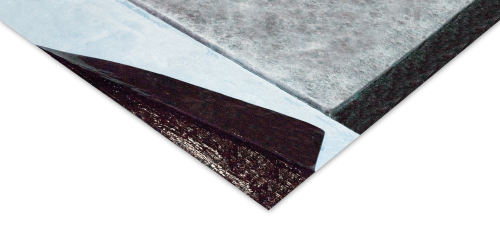

COLPLY ADHESIVE is a high quality, single component, asphalt cutback adhesive formulated specifically for adhering SBS-modified bitumen membrane systems. COLPLY ADHESIVE is blended with specially selected and processed asphalt and performance additives that contribute to its smooth troweling consistency.

Product Properties

- Overlying Material SBS Membrane

Installation

COLPLY ADHESIVE is applied to approved substrates using a trowel, v-notched squeegee or sprayer. Apply COLPLY ADHESIVE at a rate of 1.5 to 2.5 gal per square over smooth surfaces. The application rate over irregular/porous surfaces will vary, adjust rates to ensure full coverage.

Testing & Approvals

Related Products

SOPRASEAL STICK FLASHPRO

SOPRASEAL STICK FLASHPRO is a 17mil, self-adhesive, air and vapor barrier flashing membrane composed of a polymer-based adhesive and a…

View Product

2-1 SOPRASMART BOARD

2-1 SOPRASMART BOARD is a high-performance factory laminated panel combining an SBS-modified bitumen base membrane and SOPRABOARD an asphaltic roof…

View Product

ALSAN® TRAFIK RS 733 PART A

ALSAN TRAFIK RS 733 Part A is a high-performance rapid-setting, polymethyl methacrylate (PMMA) resin. ALSAN TRAFIK RS 733 PART A…

View ProductRelated Projects

American Airlines Center – Dallas, Texas

On March 21, 2022, a leaky roof on Dallas' American Airlines Center delayed the start of an NBA game between the hometown Mavericks and the Minnesota Timberwolves, and after the issue surfaced again a couple months later to interfere with a Mavs playoff game, quick action was needed to replace the building's 20-year-old roof.

DFW International Airport – Dallas, Texas

The Dallas Fort Worth International Airport (DFW) became one of the first major U.S. airports to go carbon neutral in 2016, and since then, the facility has only accelerated its sustainability efforts. When ELASTOPHENE® and SOPRALENE® with ECO3 granules were specified for the roofs of DFW’s Terminal F Skylink buildings, it represented a new level of commitment to our planet.