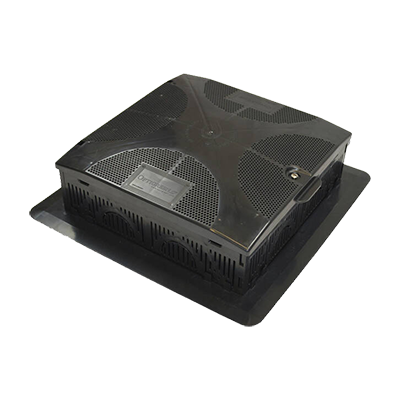

COLVENT™ 180 TG SKU: 00383

COLVENT™ 180 TG SKU: 00383

COLVENT 180 TG is a SBS-modified bitumen membrane used in roofing assemblies. COLVENT 180 TG is reinforced with a tough, dimensionally stable non-woven polyester mat that is saturated and coated on both sides with a proprietary formulation of elastomeric styrene-butadiene-styrene (SBS) polymer modified bitumen.

Product Properties

- ASTM ASTM D6164

- Component Base

- Installation Method Heat Welded

- Reinforcement Polyester

- Thickness (minimum) 110 mils (2.8 mm)

- Thickness (nominal) 118 mils (3.0 mm)

- Topside Sanded

- Underside Burn Off Film

Installation

Prior to installation, unroll COLVENT 180 TG onto the roof surface and allow to relax. Place COLVENT 180 TG in desired position and back roll the product. COLVENT 180 TG is then heat welded to approved substrates. Subsequent approved inter-ply or cap ply membranes are applied to COLVENT 180 TG via heat welding.

Testing & Approvals

Related Products

SOPRALAST® 50 TV ALU

SOPRALAST 50 TV ALU is a SBS-modified bitumen membrane used in roofing assemblies. SOPRALAST 50 TV ALU is reinforced with…

View Product

SOPRANATURE® DRAIN BOX

Manufactured from recycled acrylonitrile-butadiene-styrene (ABS) with narrow slots on the sidewalls and small holes on the top cover, SOPRANATURE DRAIN…

View Product

SOPRASEAL® STICK VP

SOPRASEAL STICK VP is a lightweight 24-mil self-adhered, vapor-permeable, water-resistive air barrier used in wall construction. SOPRASEAL STICK VP is…

View ProductRelated Projects

Bellevue Hospital Center – New York, New York

Bellevue, the nations oldest medical center, is protected by SOPREMA’s ALSAN RS 260 LO PMA liquid membrane technology. In the dead of winter, with strict project parameters, SOPREMA’s ALSAN RS created an impenetrable liquid waterproofing membrane guaranteed to be waterproof for 20 years with a life expectancy of 25 to 30 years.

Cleveland Clinic – Cleveland, Ohio

Cleveland Clinic’s main campus consists of 41 buildings on about 140 acres near University Circle, Cleveland. They operate 14 family health and ambulatory surgery centers in surrounding communities and a multispecialty hospital and family health center in Weston, Florida. Various SOPREMA® systems have been chosen for their waterproofing needs.