ELASTOPHENE® PS 3.0 SKU: 00504

ELASTOPHENE® PS 3.0 SKU: 00504

ELASTOPHENE® PS 3.0 is an SBS-modified bitumen base ply for use in approved multi-ply membrane and flashing assemblies. ELASTOPHENE PS 3.0 is composed of a proprietary formulation of elastomeric styrene-butadiene-styrene (SBS) polymer modified bitumen and is a reinforced with high quality random glass fiber mat. The topside is surfaced with polyolefin burn-off film and the underside is surfaced with fine mineral aggregate to facilitate cold adhesive and hot asphalt applications.

Product Properties

- ASTM ASTM D6163

- Component Base

- Installation Method Cold Adhered, Asphalt Adhered

- Reinforcement Glass Scrim

- Thickness (minimum) 110 mils (2.8 mm)

- Thickness (nominal) 118 mils (3.0 mm)

- Topside Burn Off Film

- Underside Sanded

Installation

Prior to installation, unroll ELASTOPHENE PS 3.0 onto the roof surface and allow to relax. Place ELASTOPHENE PS 3.0 in desired position and back roll the product. Apply approved cold adhesive or hot asphalt following manufacturer specifications. ELASTOPHENE PS 3.0 is then rolled into the cold adhesive or hot asphalt and subsequently rolled with a weighted roller. Subsequent approved inter-ply or cap ply membranes are applied to ELASTOPHENE PS 3.0 via heat welding. Refer to the SOPREMA SBS Roofing Manual for additional application guidelines.

Testing & Approvals

Related Products

SOPREMA® Modified Drip Edge

SOPREMA® Modified Drip Edge is engineered with an interlocking, concealed splice plate designed to prevent splice plate migration under the…

View Product

ELASTOCOL™ 500

ELASTOCOL 500 is an asphalt based primer for use in approved multi-ply membrane and flashing assemblies. ELASTOCOL 500 is composed…

View Product

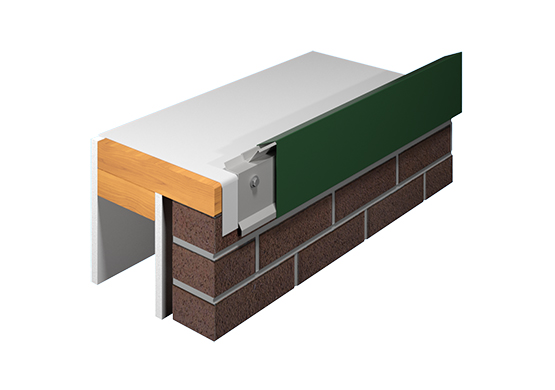

SOPRA-EDGE SENTINEL® Fascia

SOPRA-EDGE SENTINEL® Fascia is manufactured in 12 foot lengths with pre-punched fastening holes in the galvanized water dam to ensure…

View ProductRelated Projects

ANB Bank – Denver, Colorado

When the Denver ANB Bank was to go through a remodel, SOPREMA’s COLPHENE® LM BARR product was selected to waterproof the building. With a tight deadline and existing concrete preparation to take into consideration, COLPHENE LM BARR was the perfect solution due to its excellent performance qualities. With COLPHENE LM BARR’s STPE moisture cure technology, the new and improved ANB Bank will have a continuous waterproofing layer that can withstand extreme cold and high temperatures without cracking or softening for many years to come.

John R. Oishei Children’s Hospital – Buffalo, New York

SOPREMA’s SOPRASEAL® Xpress G air and vapor barrier was ideal for this project. The exterior grade, inorganic faced gypsum board with an air and vapor barrier factory applied to the exterior surface, is the first and only ABAA evaluated assembly. SOPRASEAL® Xpress G boards are mechanically fastened to the structure using corrosion resistant SOPRASEAL® Xpress G Screws. A 6 inch self-adhered strip of SOPRASEAL® Stick 1100T is then installed over all board joints.