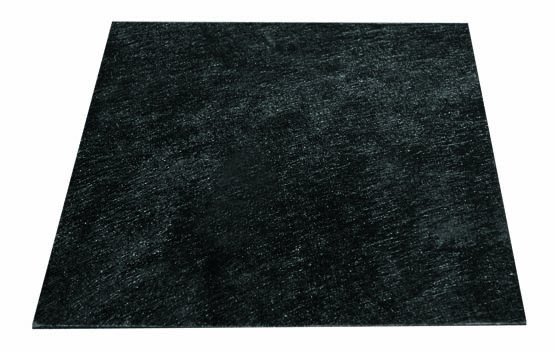

SOPRABOARD® SKU: D08415

SOPRABOARD® SKU: D08415

SOPRABOARD asphaltic cover board is a semi-rigid roofing substrate board for use in multi-ply modified bitumen membrane and flashing assemblies and also serves as a protection board for waterproofing applications. SOPRABOARD is composed of a mineral fortified asphaltic core formed between two fiberglass reinforcing plies and is available in variety of lengths and thicknesses.

Product Properties

- Material Asphaltic

- Type Board

- Use Coverboard

Installation

Place SOPRABOARD in desired position. Butt edges and stagger joints of adjacent boards. Secure boards to substrate using mechanical fasteners, insulation adhesive or hot asphalt. For approvals and listings to meet project-specific wind rating requirements, contact SOPREMA.

Refer to the SOPREMA Low-Slope Roofing Insulation Technical Manual for complete application guidelines.

Testing & Approvals

Related Products

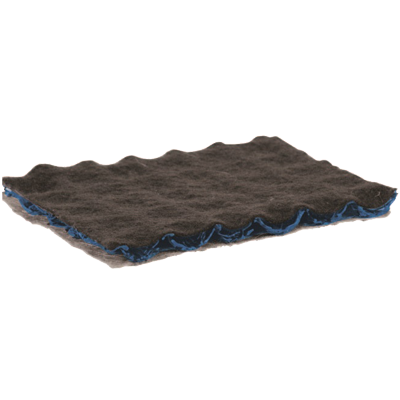

INSONO AF3-90

INSONO AF3-90 is composed of self-adhesive elastomeric bitumen with an exposed non-woven polyester reinforcement. The underside is surfaced with a…

View Product

SOPRADRAIN™ ECOVENT 2

SOPRADRAIN ECOVENT 2 is a geometric patterned core drainage mat designed to eliminate hydrostatic pressure on vegetated roofs, foundation walls,…

View Product

SENTINEL® UNIVERSAL SEALANT

SENTINEL UNIVERSAL SEALANT is a moisture-cured, polyether, elastomeric sealant for use in approved SENTINEL PVC membrane and flashing assemblies. SENTINEL…

View ProductRelated Projects

Verizon Bowdoin Square – Boston, Massachusetts

At Bowdoin Square, which is at the corner of Bowdoin and Cambridge Streets, is a white office building that has many interesting details throughout.

Walter Reed Community Center – Arlington, Virginia

From the beginning, the architect designing the Walter Reed Community Center was asked to include a vegetative roof within the blueprints. The goal was a LEED certified Silver level building.