SENTINEL® KEE PREFABRICATED CORNERS SKU: P624, P625

SENTINEL® KEE PREFABRICATED CORNERS SKU: P624, P625

SENTINEL KEE PREFABRICATED CORNERS are manufactured from fiberglass reinforced 60 mil KEE membrane and intended to flash 90 degree outside and inside corners.

Product Properties

- Type Membrane Accessories

Installation

SENTINEL KEE PREFABRICATED CORNERS are installed to the membrane using a hot air welder.

Contact SOPREMA or refer to published guidelines for additional details and application requirements.

Related Products

ELASTOPHENE® FLAM FR GR

ELASTOPHENE® Flam FR GR (fire retardant, granulated) is an SBS-modified bitumen cap ply for use in approved multi-ply membrane and…

View Product

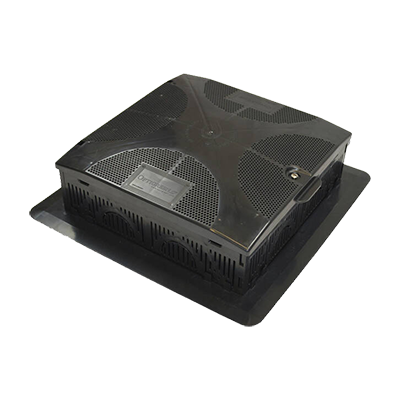

SOPRANATURE® DRAIN BOX

Manufactured from recycled acrylonitrile-butadiene-styrene (ABS) with narrow slots on the sidewalls and small holes on the top cover, SOPRANATURE DRAIN…

View Product

SOPRABOARD®

SOPRABOARD asphaltic cover board is a semi-rigid roofing substrate board for use in multi-ply modified bitumen membrane and flashing assemblies…

View ProductRelated Projects

The Metropolitan Museum of Art – New York City, New York

SOPREMA® waterproofing products were used during the museum’s expansion including COLPHENE® 3000 to provide watertight solutions for the foundation. This self-adhered waterproofing system is a flexible, versatile, dependable, roll-type waterproofing membrane.

Placer County Water Agency – Auburn, California

In 2015, the Placer County Water Agency took on a tear-off roofing project, in which SOPREMA products were used. SOPREMA was the right choice for this project because the breadth of products met the designer’s needs, including meeting California Title 24 energy efficiency standards with the use of ENERGY STAR® rated SOPRASTAR® Flam. Another appealing aspect was the versatility of SENTINEL® P150, which allowed coverage for the vertical walls throughout the roofing system.