SOPRAFLASH™ R SKU: W301

SOPRAFLASH™ R SKU: W301

SOPRAFLASH R is a lightweight, thermally bonded, spunlaid polyester/nylon composite mat. SOPRAFLASH R is a reinforcing non-woven mesh used to reinforce SOPREMA’s waterproofing liquid membranes such as COLPHENE H, COLPHENE H-EV, COLPHENE LM BARR and COLPHENE LM BARR SPRAY.

Product Properties

- Material Reinforcement

Installation

Refer to the COLPHENE H, COLPHENE H-EV, COLPHENE LM BARR or COLPHENE LM BARR SPRAY application guidelines for complete details. Immediately install SOPRAFLASH R into the wet first lift to ensure membrane strike through. Overlap SOPRAFLASH R to a minimum of 1 in to allow for complete coverage of the liquid waterproofing products.

Testing & Approvals

Related Products

ALSAN® RS 222 Primer

ALSAN RS 222 PRIMER is a rapid-setting, proprietary formulation polymethyl methacrylate (PMMA) primer. ALSAN RS 222 PRIMER is used to…

View Product

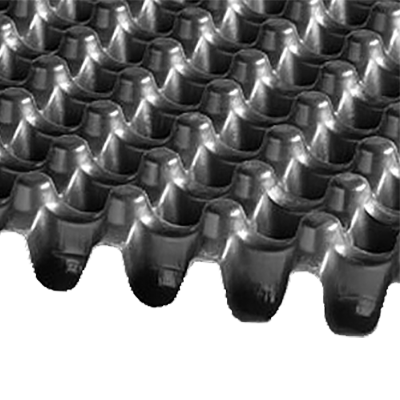

SOPRANATURE® DRAIN PLATE 40

SOPRANATURE DRAIN PLATE 40 is a 1.5 in tall, three-dimensional plastic drainage structure for green roofing systems. Unlike thin, flexible…

View Product

ULTRA-STICK® NAIL BASE

ULTRA-STICK Nail Base is an SBS-modified bitumen nail base sheet for use in approved multi-ply membrane assemblies over nailable deck….

View ProductRelated Projects

TD Bank – Boston, Massachusetts

In 2017, TD Bank expanded its locations to South Boston, Massachusetts. When looking for a vapor permeable spray application with multiple advantages, SOPREMA’s SOPRASEAL® LM 202 VP was selected.

Deer Meadow Primary School – Greencastle, Indiana

Deer Meadow Primary School is a public elementary school located in Greencastle, IN. Designed with highly visible roofing architectural appearance on all sides of the building, a roofing membrane with color matching aesthetics and long-term performance was needed. SOPREMA®’s SENTINEL® Copper Art P150 HFB PVC was a perfect fit.