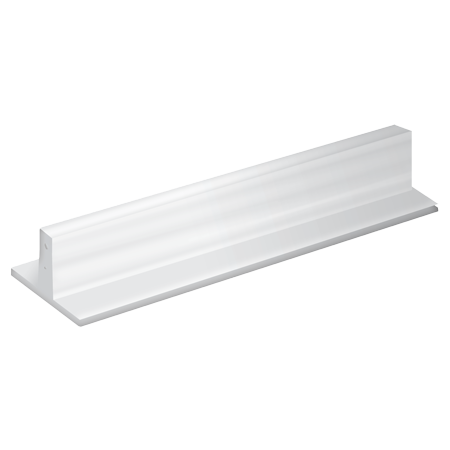

SOPRALAST® 50 TV ALU SANDED SKU: 05151

SOPRALAST® 50 TV ALU SANDED SKU: 05151

SOPRALAST 50 TV ALU SANDED is a SBS-modified bitumen membrane used in roofing assemblies. SOPRALAST 50 TV ALU SANDED is reinforced with a glass fiber scrim that is saturated and coated on both sides with a proprietary formulation of elastomeric styrene-butadiene-styrene (SBS) polymer modified bitumen.

Product Properties

- ASTM ASTM D6298

- Component Cap

- Installation Method Cold Adhered, Asphalt Adhered

- Reinforcement Glass Scrim

- Thickness (minimum) 150 mils (3.8 mm)

- Thickness (nominal) 157 mils (4.0 mm)

- Topside Reflective Foil

- Underside Sanded

Installation

Prior to installation, unroll SOPRALAST 50 TV ALU SANDED onto the roof surface and allow to relax. Place SOPRALAST 50 TV ALU SANDED in desired position and back roll the product. Apply approved cold adhesive following manufacturer specifications. SOPRALAST 50 TV ALU SANDED is then rolled into the cold adhesive and subsequently rolled with a weighted roller.

Testing & Approvals

Related Products

SOPRANATURE® MRB 30

SOPRANATURE MRB 30 is a moisture retention board with drainage properties made from 100% recycled polyester. SOPRANATURE MRB 30 is…

View Product

SENTINEL® PVC PROFILE BARS

SENTINEL PVC PROFILE BARS are extruded, pliable PVC bars designed to provide SENTINEL PVC and KEE membranes with the appearance…

View Product

ALSAN® COATING SIL 402

ALSAN COATING SIL 402 is a high solids, single component, silicone roof coating and protective barrier for various low-slope…

View ProductRelated Projects

U.S. Treasury Building – Washington DC

The Treasury Building is the oldest departmental building in Washington and has had a great impact on the design of other governmental buildings. At the time of its completion, it was one of the largest office buildings in the world.

American Airlines Trinity Campus – Fort Worth, Texas

When American Airlines, the world’s largest airline by fleet size, wanted to bring 12,000 employees together at a centralized location, it was a big job, to say the least.