COLPLY® EF ADHESIVE SKU: A216, A220, A221

COLPLY® EF ADHESIVE SKU: A216, A220, A221

COLPLY EF ADHESIVE (environmentally friendly) is a moisture cure, single-component membrane adhesive using a highly advanced Silyl-Terminated Polyether (STPE) polymer. Due to its polymer composition, once cured, COLPLY EF ADHESIVE provides an additional layer of elastomeric waterproofing protection between membrane plies.

Product Properties

- Overlying Material SBS Membrane

Installation

COLPLY EF ADHESIVE is applied to approved substrates using a squeegee or an application cart for ribbon adhesive application. Thoroughly mix container before use. Apply COLPLY EF ADHESIVE at 1.5 to 2 gallons per 100 square feet for sand-surfaced inter-ply applications and 2 gallons per 100 square feet for ribbon application.

Testing & Approvals

Related Products

ALSAN® TRAFIK RS 733 SELF-LEVELING MORTAR

ALSAN TRAFIK RS 733 Self-Leveling Mortar is created by combining ALSAN TRAFIK RS 733 Part A and ALSAN TRAFIK RS…

View Product

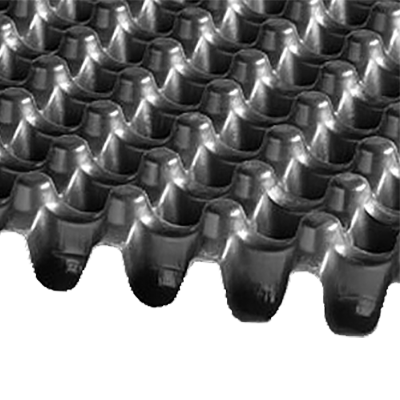

SOPRANATURE® DRAIN PLATE 40

SOPRANATURE DRAIN PLATE 40 is a 1.5 in tall, three-dimensional plastic drainage structure for green roofing systems. Unlike thin, flexible…

View Product

SOPRAFLOR X

SOPRANATURE SOPRAFLOR X is a growing medium formulated for extensive non-irrigated and low-maintenance SOPRANATURE systems. SOPRANATURE SOPRAFLOR X has a…

View ProductRelated Projects

TD Bank – Boston, Massachusetts

In 2017, TD Bank expanded its locations to South Boston, Massachusetts. When looking for a vapor permeable spray application with multiple advantages, SOPREMA’s SOPRASEAL® LM 202 VP was selected.

The Westin Savannah Harbor – Savannah, Georgia

The Westin was due for a roof replacement on 17,828 square feet of its property. To complete the project, SOPREMA’s SOPRAISO ™, DUOTACK®, SENTINEL® P-150, and ALSAN® RS 230 Flash were selected. These products allowed for the design to meet FM 1-120 codes and the use of ALSAN RS 230 Flash solved any difficult flashing details which was only one of many reasons

SOPREMA products were selected.