ELASTOPHENE® FLAM HS SKU: 00399

ELASTOPHENE® FLAM HS SKU: 00399

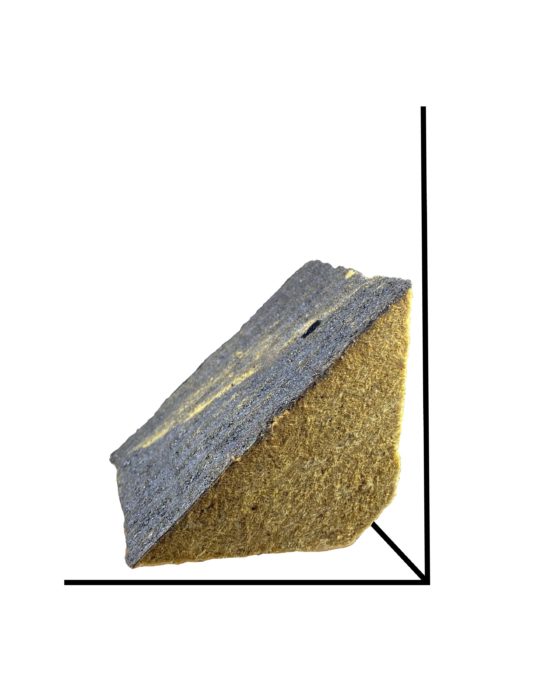

ELASTOPHENE® Flam HS (high strength) is an SBS-modified bitumen base ply for use in approved multi-ply membrane and flashing assemblies. ELASTOPHENE Flam HS is composed of a proprietary formulation of elastomeric styrene-butadiene-styrene (SBS) polymer modified bitumen and is reinforced with tough, dimensionally stable composite polyester/glass fiber reinforcement. The topside and underside are surfaced with polyolefin burn-off film to optimize heat welding.

Product Properties

- ASTM ASTM D6162

- Component Base

- Installation Method Heat Welded

- Reinforcement Composite

- Thickness (minimum) 110 mils (2.8 mm)

- Thickness (nominal) 118 mils (3.0 mm)

- Topside Burn Off Film

- Underside Burn Off Film

Installation

Prior to installation, unroll ELASTOPHENE Flam HS onto the roof surface and allow to relax. Position ELASTOPHENE Flam HS in desired position and back roll the product. ELASTOPHENE Flam HS is then heat welded to approved substrates. Subsequent approved inter-ply or cap ply membranes are applied to ELASTOPHENE Flam HS via heat welding. Refer to the SOPREMA SBS Roofing Manual for additional application guidelines.

Related Products

ALSAN® FLASHING KIT

SOPREMA’S ALSAN Flashing Kit provides you with everything you need to make fast, permanent repairs and flashings. Designed with efficiency…

View Product

ANTIROCK®

ANTIROCK is an SBS-modified bitumen membrane designed to waterproof bridge decks. ANTIROCK is reinforced with a tough, dimensionally stable non-woven…

View Product

SOPRAROCK Cant Strips

SOPRAROCK CANT STRIPS are a rigid mineral wool cant, coated with a bitumen and lightly sanded surface. SOPRAROCK CANT STRIPS…

View ProductRelated Projects

Potomac Transportation Center – Dumfries, Virginia

To stay proactive, The Potomac Transportation Center, part of the Prince William County Public Schools, decided to apply a protective coating to their rooftop. Although there were no immediate problems with the current roof, it was determined that a preventative coating was needed on the aging roof before future complications arose. When it came time to select products for this job, the ALSAN® Coating line was selected due to SOPREMA’s relationship with Northeast Contracting Corporation, a 2018 Mammouth Club Member, and the expert local field technical services team.