ELASTOPHENE® SANDED 3.0 SKU: 00251

ELASTOPHENE® SANDED 3.0 SKU: 00251

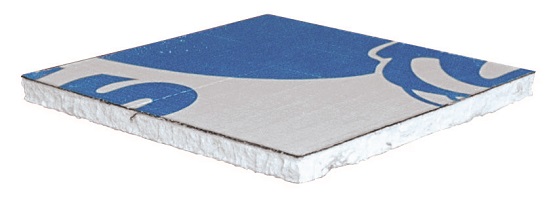

ELASTOPHENE® Sanded 3.0 is an SBS-modified bitumen base ply for use in approved multi-ply membrane and flashing assemblies. ELASTOPHENE Sanded 3.0 is composed of a proprietary formulation of elastomeric styrene-butadiene-styrene (SBS) polymer modified bitumen and is reinforced with a high quality random glass fiber mat. The topside and underside are surfaced with fine mineral aggregate to facilitate cold adhesive and hot asphalt applications

Product Properties

- ASTM ASTM D6163

- Component Base

- Installation Method Cold Adhered

- Reinforcement Glass Fiber

- Thickness (minimum) 110 mils (2.8 mm)

- Thickness 118 mils (3.0 mm)

- Topside Sanded

- Underside Sanded

Installation

Prior to installation, unroll ELASTOPHENE Sanded 3.0 onto the roof surface and allow to relax. Place ELASTOPHENE Sanded 3.0 in desired position and back roll the product. Apply approved cold adhesive or hot asphalt following manufacturer specifications. ELASTOPHENE Sanded 3.0 is then rolled into the cold adhesive or hot asphalt and subsequently rolled with a weighted roller. Subsequent approved inter-ply or cap ply membranes are applied to ELASTOPHENE Sanded 3.0 via cold adhesive or hot asphalt. Refer to the SOPREMA SBS Roofing Manual for additional application guidelines.

Testing & Approvals

Related Products

SOPRAFIX® #14 MP FASTENER

SOPRAFIX® #14 MP (Multi Purpose) Insulation Fasteners are designed for the attachment of insulation and membrane to steel (18-22 ga.),…

View Product

SOPRASEAL® Xpress G

SOPRASEAL Xpress G is an exterior grade, inorganic faced gypsum board with an air and vapor barrier factory applied to…

View Product

SOPRAMASTIC ALU

SOPRAMASTIC ALU is a modified bitumen mastic for use in approved multi-ply membrane and flashing assemblies. SOPRAMASTIC ALU is composed…

View ProductRelated Projects

Garibaldi Square Condos – Chicago, Illinois

This award winning project is the direct result of the building owner’s resistance to using hot asphalt and torches on the roof. SOPREMA’s mechanically attached, self-adhered system was used to accommodate the building owner’s desires.

Boston Prudential Tower – Boston Massachusetts

“With SOPREMA®, we knew we were assured of experience, quality and a solid reputation,” states Jim Justus. “SOPREMA’s multi-ply system provided superior puncture and tear resistance and their past history indicated the products would exceed the owner’s requirements.