ALSAN® FLASHING SKU: 32825, 32800

ALSAN® FLASHING SKU: 32825, 32800

ALSAN FLASHING is a unique polyurethane bituminous resin specifically formulated for liquid-applied flashings, details and maintenance applications. ALSAN FLASHING utilizes either Polyfleece or ALSAN Pre-Cut Fleece that, in combination with its unique chemistry, provides an extremely durable and easy to apply flashing solution.

Product Properties

- Installation Method 1 Part

- Material Liquid

- Technology Polyurethane Bitumen

Installation

Thoroughly mix ALSAN FLASHING before use. Using a brush or roller, apply ALSAN FLASHING to the prepared substrate at a rate of 2 gal/sq. Evenly coat the surface; taking precaution not to spread too thin or pool in low areas. Install the reinforcing fabric into the first layer of flashing. Add additional flashing between reinforcing fabric overlaps, to avoid dry lap conditions. With a roller or brush, embed the reinforcing fabric into the ALSAN FLASHING; eliminating any voids, ridges, air pockets, etc. Next generously apply a second layer of ALSAN FLASHING extending a minimum of 1 in beyond the reinforcing fabric, fully encapsulating the reinforcing fabric at a rate of 2 gal/sq. Once cured, apply the final coat of ALSAN FLASHING, at a rate of 2 gal/sq.

Testing & Approvals

Related Products

ELASTOPHENE® ULTRA-STICK

ELASTOPHENE ULTRA-STICK is an SBS-modified bitumen, self-adhered base sheet for use in approved multi-ply membrane and flashing assemblies. ELASTOPHENE ULTRA-STICK…

View Product

ALSAN Trafik PU 421

ALSAN Trafik PU 421 is a two-component, low odor, aliphatic polyurethane elastomeric topcoat. This topcoat provides excellent adhesion to SOPREMA…

View Product

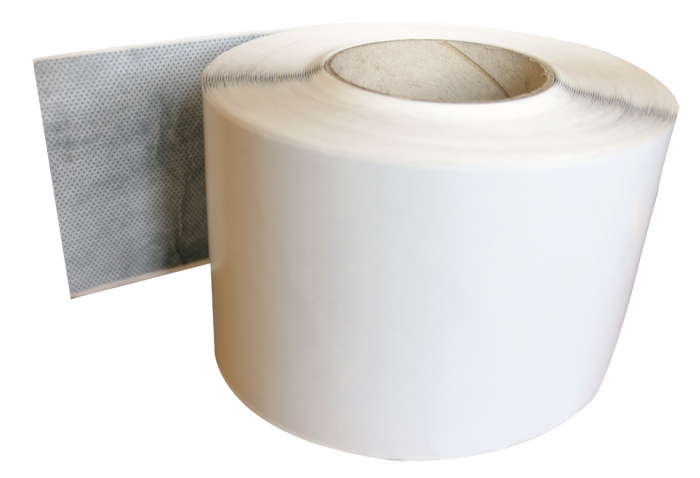

ALSAN® COATING BUTYL FLEECE TAPE

ALSAN COATING BUTYL FLEECE TAPE contains a butyl rubber compound with a polyester fleece face used where required or recommended…

View ProductRelated Projects

Northeast Louisiana State Office Building – Monroe, Louisiana

As an approved manufacturer for the State of Louisiana, the decision makers at the Facility Planning and Control Department were assured that the products installed offered unsurpassed quality. The final assembly was designed to meet FM Approvals 1-90 wind uplift test and proves to protect the building for many years to come.