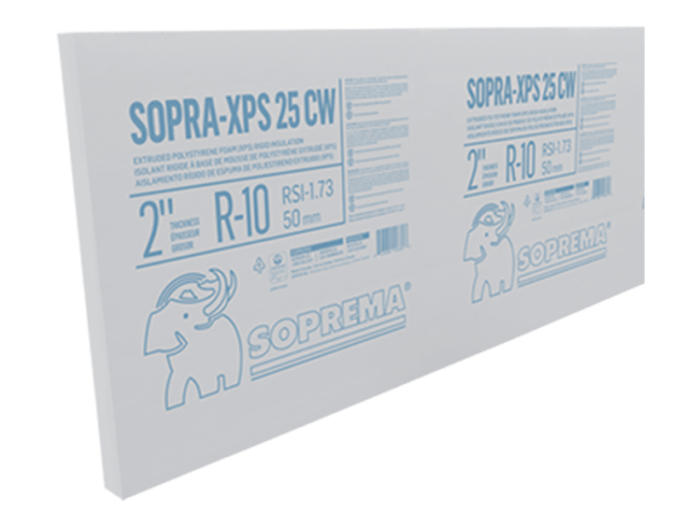

SOPRA-XPS 25 CW

SOPRA-XPS 25 CW

SOPRA-XPS 25CW are rigid thermal insulation boards made of extruded polystyrene closed-cell foam. SOPRA-XPS 25CW is mainly used as thermal insulation for above grade SOPREMA wall systems. SOPRA-XPS 25CW insulation boards are scored every 16 in (400 mm) and 24 in (600 mm) so they can easily be cut when they need to fit perfectly between wall ties.

Product Properties

- Material Extruded Polystyrene

- Use Insulation

Installation

Place SOPRA-XPS 25CW in desired position. Butt edges and stagger joints of adjacent boards. Secure boards to substrate using mechanical fasteners.

Refer to SOPREMA’s published technical literature for additional details and application requirements.

Related Products

ALSAN® COATING SIL 402

ALSAN COATING SIL 402 is a high solids, single component, silicone roof coating and protective barrier for various low-slope…

View Product

COLPHENE® LM BARR

COLPHENE® LM BARR is a single component with 98% solids content and a liquid-applied, moisture-curing elastomeric waterproofing membrane.

View Product

SENTINEL® KEE PREFABRICATED CORNERS

SENTINEL KEE PREFABRICATED CORNERS are manufactured from fiberglass reinforced 60 mil KEE membrane and intended to flash 90 degree outside…

View ProductRelated Projects

Holiday Inn Express – Medina, Ohio

SOPREMA®’s SOPRASEAL® Stick VP self-adhered vapor-permeable air barrier membrane was installed to ensure a continuous air barrier with no moisture infiltration for this wall assembly requiring a “breathable” characteristic. It creates a solid barrier against air infiltration and exfiltration, which minimizes associated energy loss and condensation problems.

American Airlines Center – Dallas, Texas

On March 21, 2022, a leaky roof on Dallas' American Airlines Center delayed the start of an NBA game between the hometown Mavericks and the Minnesota Timberwolves, and after the issue surfaced again a couple months later to interfere with a Mavs playoff game, quick action was needed to replace the building's 20-year-old roof.